Suitable for large, medium, and small hospitals, research institutes, etc

Advanced Self-Shielding Technology

Advanced Self-Shielding Technology

Comprehensive shielding with various materials for multi-radiation protection, ensuring personnel safety from radiation exposure.

Efficient Target System

Efficient Target System

Isotope production area with dual cooling systems to ensure efficient reaction.

Advanced Intelligent Control System

Advanced Intelligent Control System

Intelligent control system with multiple signal detectors for automatic control of nuclide production.

Long-Lifetime Pluggable Ion Source

Long-Lifetime Pluggable Ion Source

Provides high-quality ions for acceleration; efficient, compact, and easy to maintain.

Comprehensive Machine Debugging and Reliability Assurance

Comprehensive Machine Debugging and Reliability Assurance

Full-process quality assurance system from factory production to installation and operation.

High-Precision Isochronous Magnets

High-Precision Isochronous Magnets

CNC-machined high-precision magnets that achieve and surpass accelerator physical design requirements.

Stable High-Frequency System

Stable High-Frequency System

Equipped with solid-state technology for high-frequency power feed, ensuring stable energy supply for the beam.

Outstanding Particle Dynamics Design

Outstanding Particle Dynamics Design

Cutting-edge physical design and numerical simulation to deliver stable and reliable high-quality beam output.

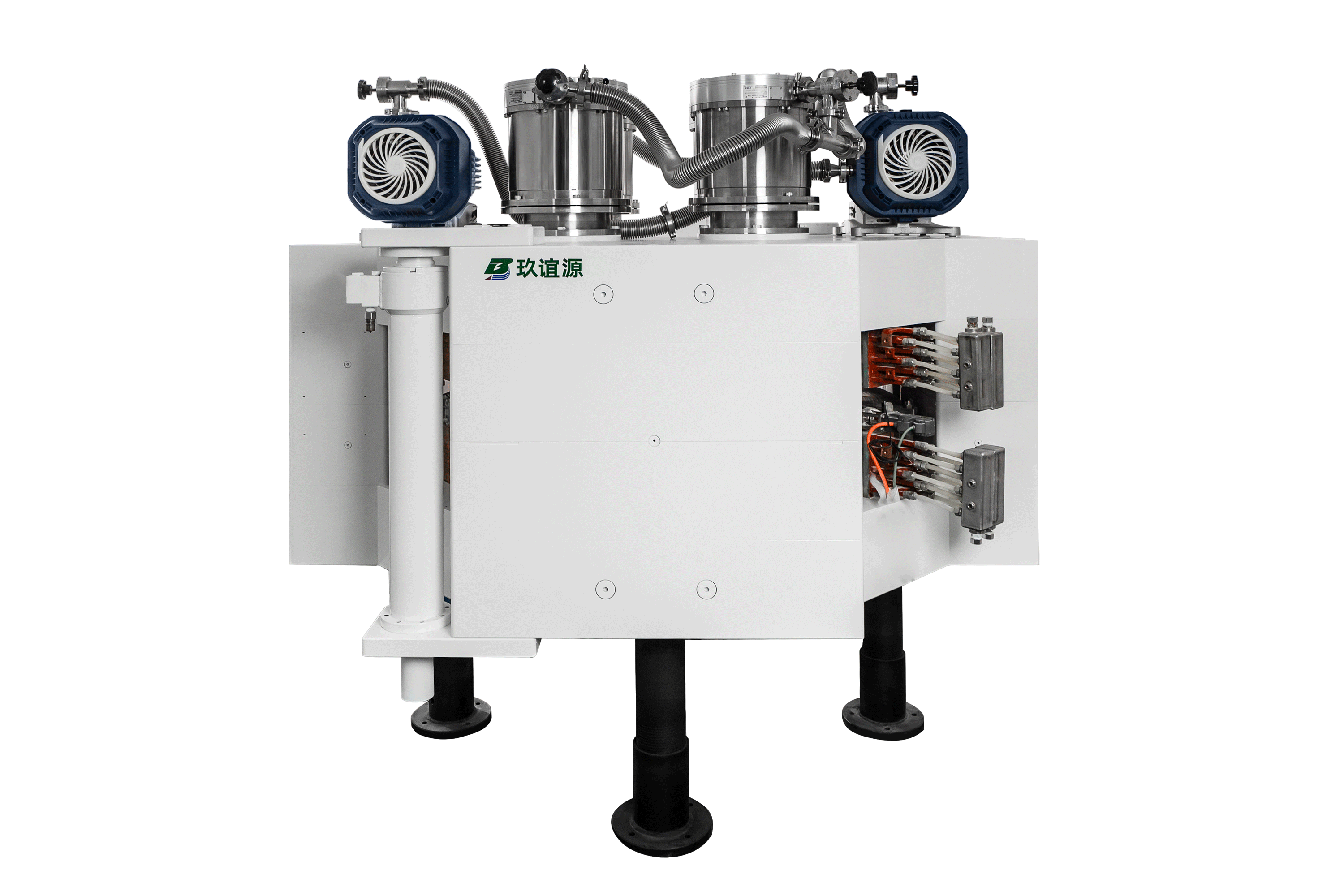

The LB-11 medical cyclotron, developed by LBT, leverages years of expertise in R&D, production, and user feedback from the "LB" series of cyclotrons. This model is engineered to enhance capabilities by supporting the production of common isotopes and integrating with solid target systems.

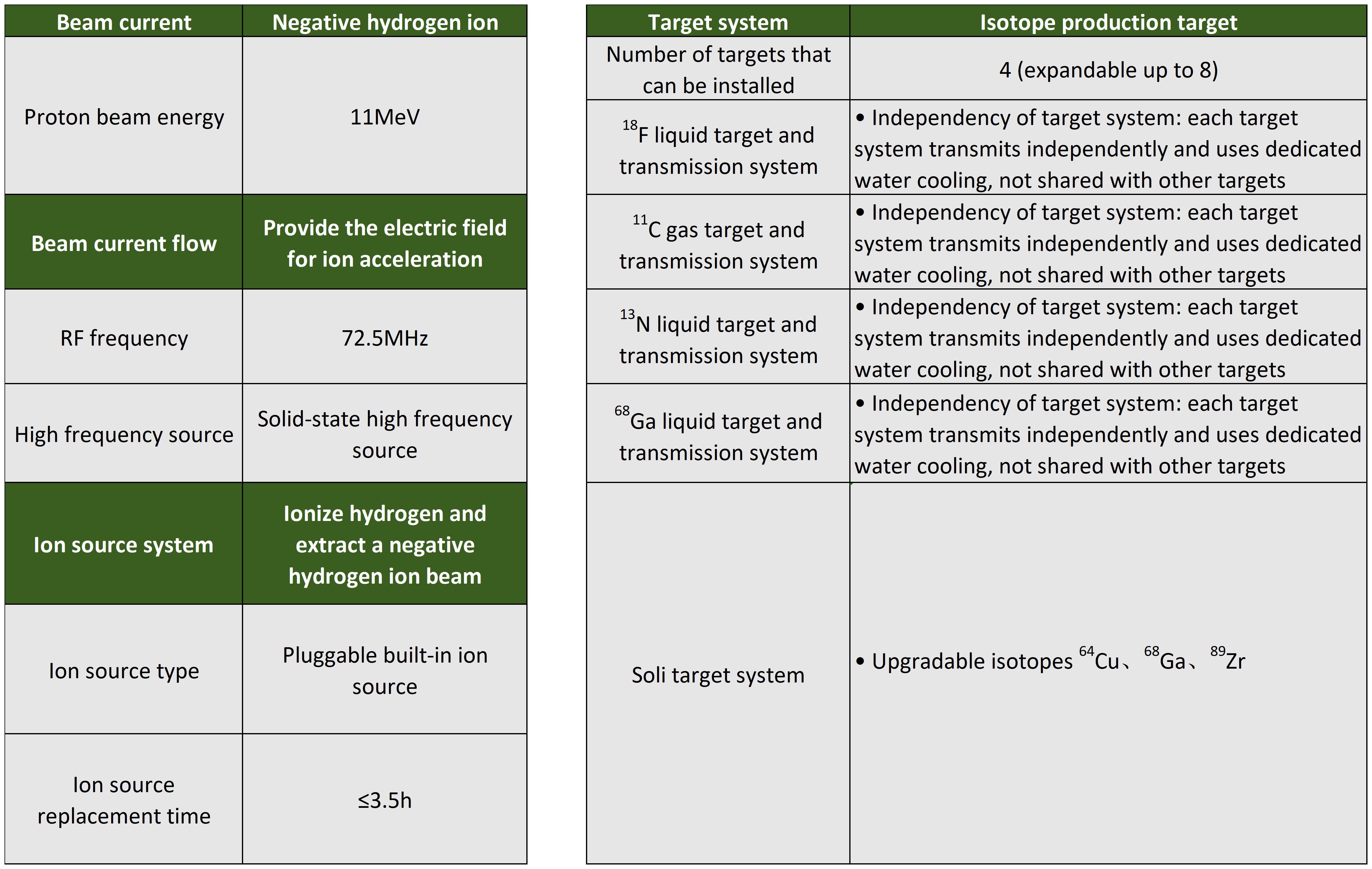

The LB-11 ion source system features entirely proprietary intellectual property, utilizing an integrated Panning ion source model with innovative power and mechanical design. ISS1101 boasts the industry's longest lifespan, capable of stable use for over 300 days*.

|

Compact Design |

Integrated, with a height of only 5 cm |

|

Pluggable Design |

Replacement time is only 3.5 hours |

|

Liquid target -material |

Niobium |

|

Gas target- material |

5N Aluminum |

|

Target window |

Havar foil |

|

Collimator material |

5N Aluminum |

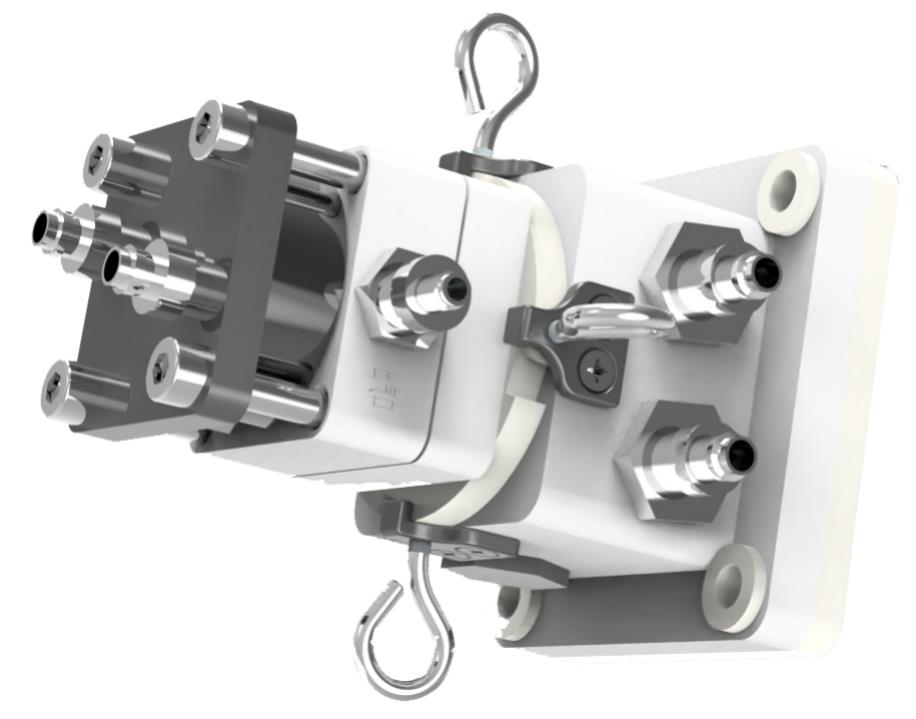

The fully automated solid target system employs unique engineering technology that allows the target plate to tilt automatically, enabling the beam to bombard the target material at an oblique angle. This design effectively increases the reaction area, boosting radionuclide yield per unit of time.

Compactly designed and highly automated, the system adapts to various radionuclide production processes within the shielding based on user needs at different stages.

The radionuclide pipelines are installed using a ferrule design, preventing cross-contamination between radionuclides while allowing for faster and more convenient assembly and replacement.

The system is equipped with three-tier administrative accesses, enabling users to customize the setup and offering software features such as report inquiry, audit tracking, and more.

LB-11 employs the latest RF system technology in the industry, utilizing a solid-state RF source composed of multiple power amplifier modules. This replaces traditional vacuum tube RF sources, significantly improving the stability of the RF system. Since each power amplifier module operates independently, damage to one module will not cause a system outage, further ensuring the stable operation of the cyclotron.

|

RF Frequency |

72.5 MHz |

|

High Stability Startup Rate |

≥ 99% |

|

Includes Backup Components |

Supports Hot Swapping |

The LB-11/12 dedicated shielding enclosure uses a combination of internal and external shielding layers to effectively absorb radiation such as neutrons and gamma rays. This reduces environmental impact according to laws and regulations, and lowers the environmental requirements for users.

|

Dimensions (mm) |

3100*3300*2200 |

|

External Dose Equivalent Rate |

≤ 10μSv/h |

|

Customizable Design Based on User Environment Conditions |

|

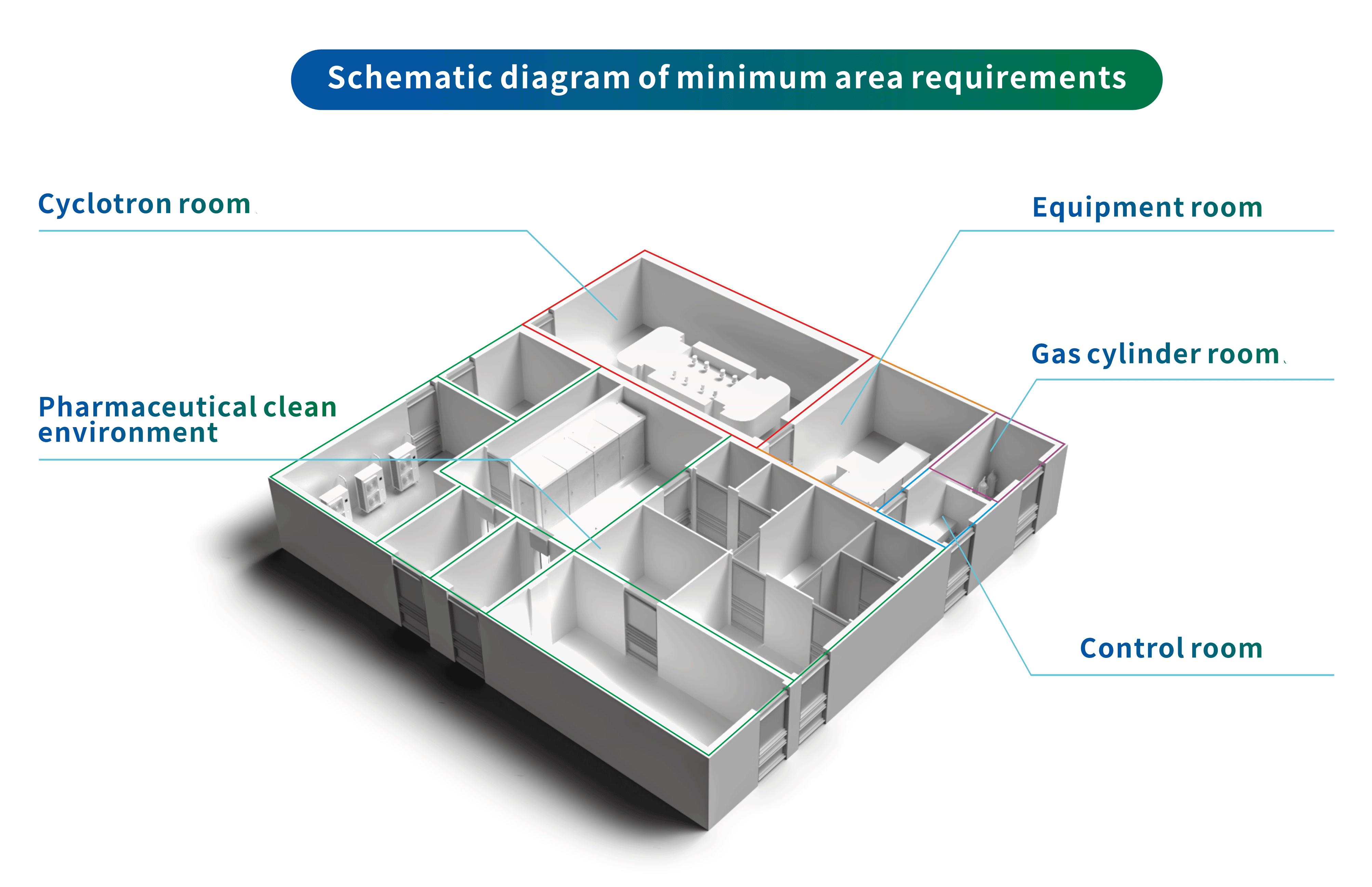

Basic function areas include the cyclotron room, the equipment room, the control room, the gas cylinder room, pharmaceutical clean environment, etc.

If equipped with a solid target system, an additional clean compressed air source interface with a pressure of no less than 0.7 MPa must be provided in both the cyclotron room (main unit area) and the hot cell area. A pressure gauge and pressure-reducing valve should be installed in the air supply line. Additionally, an extra 4N nitrogen gas interface with a pressure of no less than 0.3 MPa must be provided in the hot cell area.